Your Thermal conductivity of oak wood images are available in this site. Thermal conductivity of oak wood are a topic that is being searched for and liked by netizens today. You can Find and Download the Thermal conductivity of oak wood files here. Get all free vectors.

If you’re searching for thermal conductivity of oak wood pictures information related to the thermal conductivity of oak wood topic, you have visit the right site. Our site always gives you suggestions for downloading the maximum quality video and picture content, please kindly hunt and locate more informative video articles and images that fit your interests.

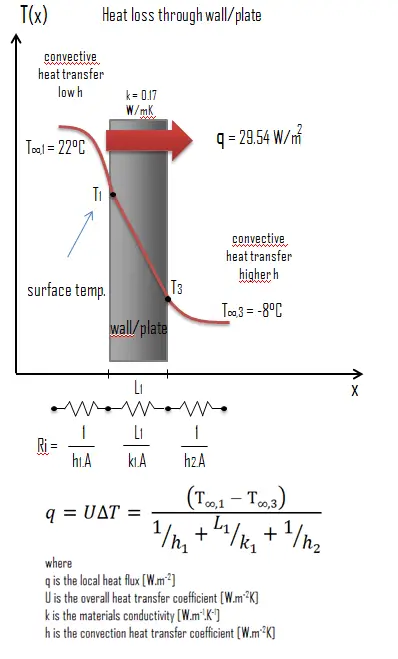

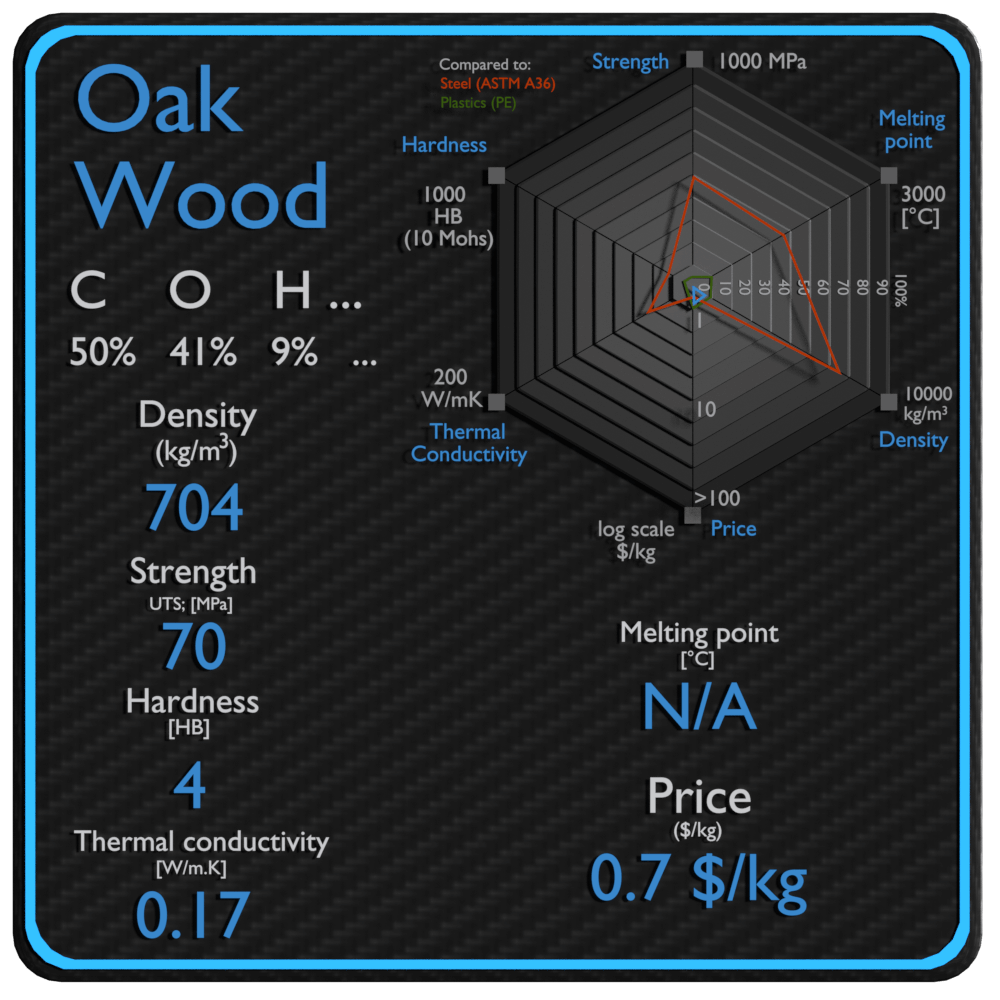

Thermal Conductivity Of Oak Wood. Material wattsm-K Copper 401 Oak 017 Balsa Wood 0048. Thermal conductivity of Oak Wood is 017 WmK. Where is thermal conductivity and represents the wood property to conduct heat. Oak wood exhibited the same decreasing tendency of changes with respect to the thermal modification temperatures.

Pdf Thermal Conductivity Of Oak Impregnated With Some Chemicals And Finished Semantic Scholar From semanticscholar.org

Pdf Thermal Conductivity Of Oak Impregnated With Some Chemicals And Finished Semantic Scholar From semanticscholar.org

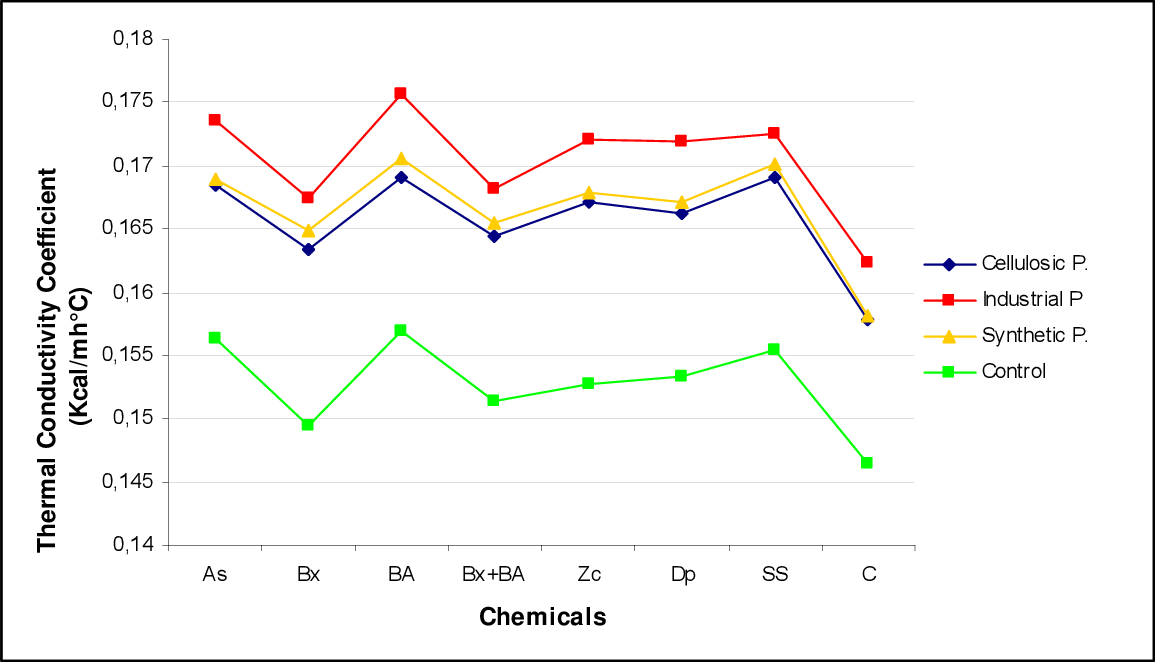

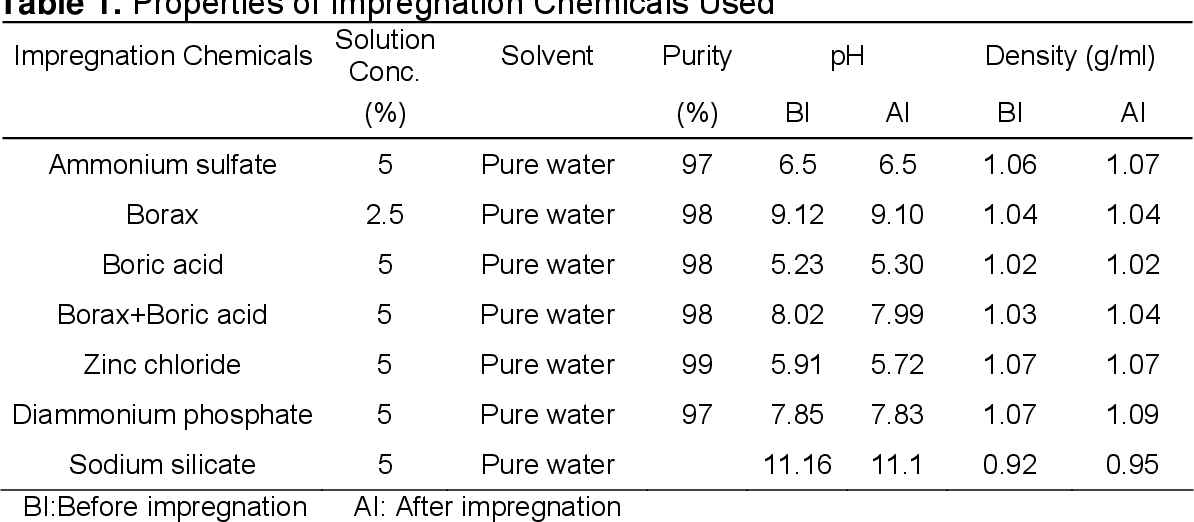

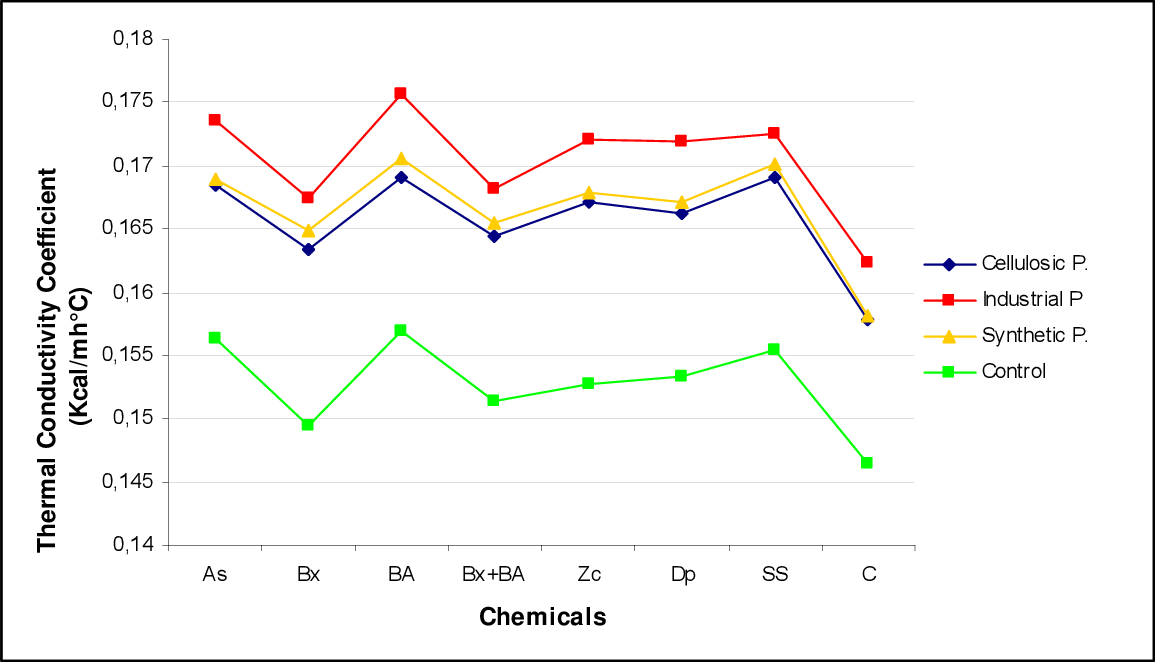

The highest thermal conductivity of 01756 KcalmhC was obtained when oak was. The highest values were obtained with boric acid and sodium silicate. This can be attributed to the lower thermal conductivity of the Japanese cypress than that of the Japanese oak as heat flux is known to correlate with thermal conductivity positively which is related to the density of wood. Because wood is a comparatively poor thermal conductor it is sometimes used to provide thermal insulation such as in log houses. The heat transfer characteristics of a solid material are measured by a property called the thermal conductivity k or λ measured in WmK. Conversely the effect of surface coating on the heat transfer was not significant.

Thermal conductivity is often measured with laser flash analysis.

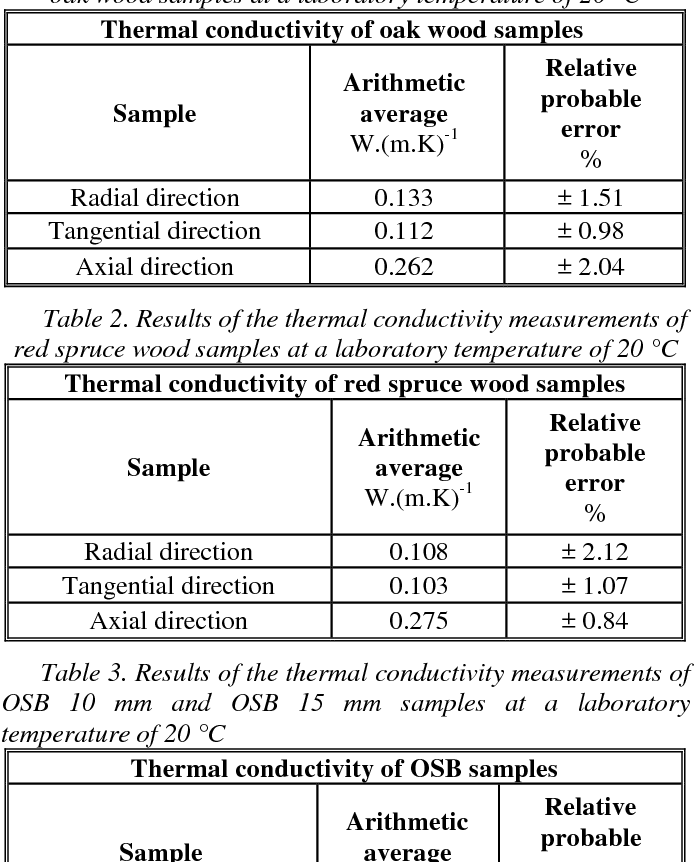

As can be seen in Table 1 thermal conductivity λ values varied according to wood species. Results show that a more careful selection of wood species for non-structural applications can be made in order to decrease energetic consumption. The lowest thermal conductivity of 01465 KcalmhC was obtained with the oak control. Results showed that the impregnation chemicals increased the thermal conductivity. For most materials the amount of heat conducted varies usually non-linearly with temperature. Then density and specific heat measurements.

Source: pinterest.com

Source: pinterest.com

Thermal conductivity is property by which we are able to distinguish wood as heat insulator or pure heat conductor. Although it is not possible to make a classify among the wood species according to thermal conductivity values of them the results can be use in plywood industry to introduce the thermal properties of plywood panels manufactured from. Is used for the calculation of the thermal conductivity and diffusivity of different wood species grown in the Northeast of Italy. Longitudinal Thermal conductivity along the grain is signif-icantly greater than across the grain. Material wattsm-K Copper 401 Oak 017 Balsa Wood 0048.

Source: researchgate.net

Source: researchgate.net

Thermal conductivity of Wood oak. Thermal conductivity is property by which we are able to distinguish wood as heat insulator or pure heat conductor. The heat conductivity of wood is dependent on a number of factors of varying degrees of importance. Results showed that the impregnation chemicals increased the thermal conductivity. Thermal Properties Metric English Comments.

Source: semanticscholar.org

Source: semanticscholar.org

Oak Wood Thermal Conductivity. In addition the thermal conductivity of painted oak was higher than that of varnished oak. The lowest thermal conductivity of 01465 KcalmhC was obtained with the oak control. This is part of the reason oak trees are so long lived and why combined with its natural water resistance oak wood is less prone to decay and rotting. Thermal Properties Metric English Comments.

Source: semanticscholar.org

Source: semanticscholar.org

Oak spruce and larch. The thermal conductivity test was performed based on the ASTM C 1113-99 hot-wire method. For most materials the amount of heat conducted varies usually non-linearly with temperature. Results show that a more careful selection of wood species for non-structural applications can be made in order to decrease energetic consumption. In spruce wood the value of coordinate b significantly increased in the case of thermal modification at 160 and 180 C by up to about 35.

Source: pinterest.com

Source: pinterest.com

Longitudinal Thermal conductivity along the grain is signif-icantly greater than across the grain. Thermal conductivity is often measured with laser flash analysis. 1 density of the wood. There have been suggestions on modelling of this problem together with measurements in earlier works especially for wet and dry wood but for char the knowledge is. Thermal Properties Metric English Comments.

Source:

Source:

The effective thermal conductivity is one of the most important parameters for modelling of thermo-chemical conversion of wood. Thermal conductivity of Oak Wood is 017 WmK. A linear relationship was achieved between thermal conductivity and density of wood. Versus radial conductivity is primarily determined by the ray cell volume in hardwoods and by the latewood volume in softwoods. Oak wood exhibited the same decreasing tendency of changes with respect to the thermal modification temperatures.

Source: pinterest.com

Source: pinterest.com

This can be attributed to the lower thermal conductivity of the Japanese cypress than that of the Japanese oak as heat flux is known to correlate with thermal conductivity positively which is related to the density of wood. The highest thermal conductivity of 01756 KcalmhC was obtained when oak was. A linear relationship was achieved between thermal conductivity and density of wood. Oak Wood Thermal Conductivity. Is used for the calculation of the thermal conductivity and diffusivity of different wood species grown in the Northeast of Italy.

Source: material-properties.org

Source: material-properties.org

The highest values were obtained with boric acid and sodium silicate. Conversely the effect of surface coating on the heat transfer was not significant. Because wood is a comparatively poor thermal conductor it is sometimes used to provide thermal insulation such as in log houses. This is part of the reason oak trees are so long lived and why combined with its natural water resistance oak wood is less prone to decay and rotting. Is used for the calculation of the thermal conductivity and diffusivity of different wood species grown in the Northeast of Italy.

Source: researchgate.net

Source: researchgate.net

Thermal Properties Metric English Comments. The heat transfer characteristics of a solid material are measured by a property called the thermal conductivity k or λ measured in WmK. In spruce wood the value of coordinate b significantly increased in the case of thermal modification at 160 and 180 C by up to about 35. Wood or PVC-U frame 00 02 02 05 03 Metal 4 mm thermal break 00 03 02 05 03 Metal 8 mm thermal break - 01 02 01 04 02 Metal 12 mm thermal break - 02 01 00 03 01 Metal 16 mm thermal break -. Thermal conductivity measurements were performed in the principal anatomical directions of European oak Quercus sp European beech Fagus sylvatica and Norway spruce Picea abies and at angles.

Source: pinterest.com

Source: pinterest.com

Thermal conductivity of Wood wool slab. The heat conductivity of wood is dependent on a number of factors of varying degrees of importance. In spruce wood the value of coordinate b significantly increased in the case of thermal modification at 160 and 180 C by up to about 35. It is a measure of a substances ability to transfer heat through a material by conduction. Oak Wood Thermal Conductivity.

In addition the thermal conductivity of painted oak was higher than that of varnished oak. In heat transfer the thermal conductivity of a substance k is an intensive property that indicates its ability to conduct heat. Thermal conductivity is often measured with laser flash analysis. Thermal conductivity of Wood wool slab. Where is thermal conductivity and represents the wood property to conduct heat.

Source: semanticscholar.org

Source: semanticscholar.org

Thermal conductivity of Wood across the grain yellow pine timber. Longitudinal Thermal conductivity along the grain is signif-icantly greater than across the grain. Results showed that the impregnation chemicals increased the thermal conductivity. The differential form of Fourier lawq ¼ grad ðT Þ 7 relates the heat flux q and the gradient of temperature. In spruce wood the value of coordinate b significantly increased in the case of thermal modification at 160 and 180 C by up to about 35.

Source: researchgate.net

Source: researchgate.net

A linear relationship was achieved between thermal conductivity and density of wood. Oak beams from the Tudor era still support the upper floors of structures that are in use on a daily basis today. Oak Wood Thermal Conductivity. Thermal conductivity of Oak Wood is 017 WmK. According to Griffiths and Kaye 1923 the ratio of longitudinal versus radial conductivity at 20 C is about 175 for.

Source: br.pinterest.com

Source: br.pinterest.com

Thermal conductivity of Wood oak. Results showed that the impregnation chemicals increased the thermal conductivity. This may be because the layer thickness of the coating. Alternative measurements are also established. Prior using the Hot-Disk samples were oven-dry to remove all humidity from their interior and consequently to avoid all influence of humidity in the measured values.

Source: researchgate.net

Source: researchgate.net

293 rows Thermal conductivity is a material property that describes ability to conduct heat. Thermal conductivity of Wood oak. Oak wood exhibited the same decreasing tendency of changes with respect to the thermal modification temperatures. In addition the thermal conductivity of painted oak was higher than that of varnished oak. In general vector of heat flux and.

Source: material-properties.org

Source: material-properties.org

Alternative measurements are also established. Oak beams from the Tudor era still support the upper floors of structures that are in use on a daily basis today. Oak Wood Thermal Conductivity. Versus radial conductivity is primarily determined by the ray cell volume in hardwoods and by the latewood volume in softwoods. Results showed that the impregnation chemicals increased the thermal conductivity.

Source: semanticscholar.org

Source: semanticscholar.org

Oak Wood Thermal Conductivity. Thermal conductivity of Wood oak. It is a measure of a substances ability to transfer heat through a material by conduction. The effective thermal conductivity is one of the most important parameters for modelling of thermo-chemical conversion of wood. Wood or PVC-U frame 00 02 02 05 03 Metal 4 mm thermal break 00 03 02 05 03 Metal 8 mm thermal break - 01 02 01 04 02 Metal 12 mm thermal break - 02 01 00 03 01 Metal 16 mm thermal break -.

Medium Relative to Other Wood. The effective thermal conductivity is one of the most important parameters for modelling of thermo-chemical conversion of wood. In spruce wood the value of coordinate b significantly increased in the case of thermal modification at 160 and 180 C by up to about 35. The thermal conductivity test was performed based on the ASTM C 1113-99 hot-wire method. 293 rows Thermal conductivity is a material property that describes ability to conduct heat.

This site is an open community for users to do submittion their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site helpful, please support us by sharing this posts to your favorite social media accounts like Facebook, Instagram and so on or you can also bookmark this blog page with the title thermal conductivity of oak wood by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.